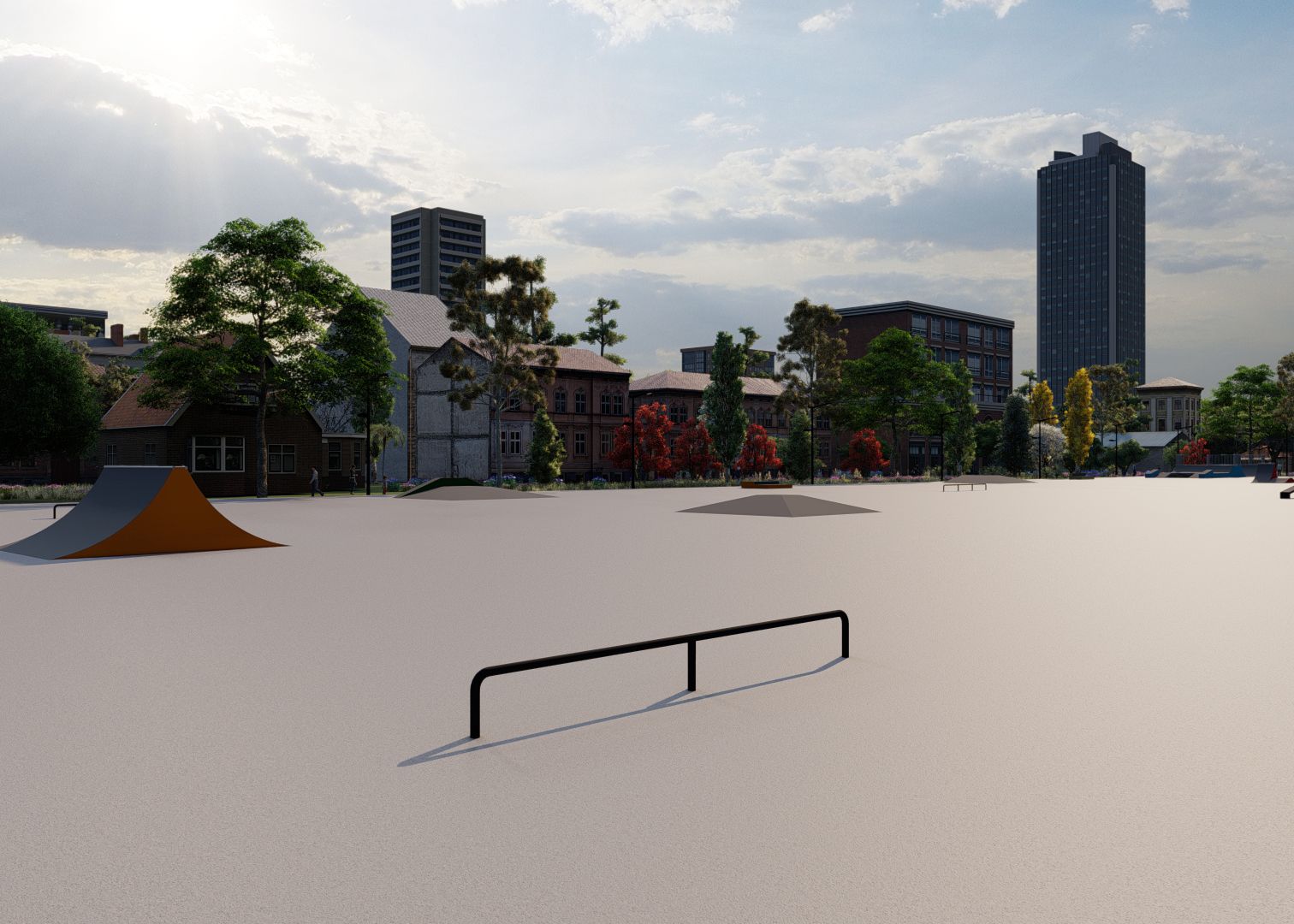

SKATE PARK - XGSLS 101 is a durable and safe skate park suitable for professional skateboarding use. Designed with high-quality materials, this track allows skateboarders to skate faster and safer. With its modern design and wide movement area, it offers a sports area that especially attracts young people. The track structure, which includes both fun and challenging obstacles, appeals to users of all ages who want to improve their skateboarding skills.

Our story started with a dream. As Cemer Playground Equipment, with the awareness of being one of the pioneers in the industry, we have been managing the whole process from idea to production based on safety for 30 years. We provide you confidence.

ASTM • ADAOur Cemer USA products meet ASTM and ADA standards;they provide safe and inclusive playgrounds.

cemer.us →