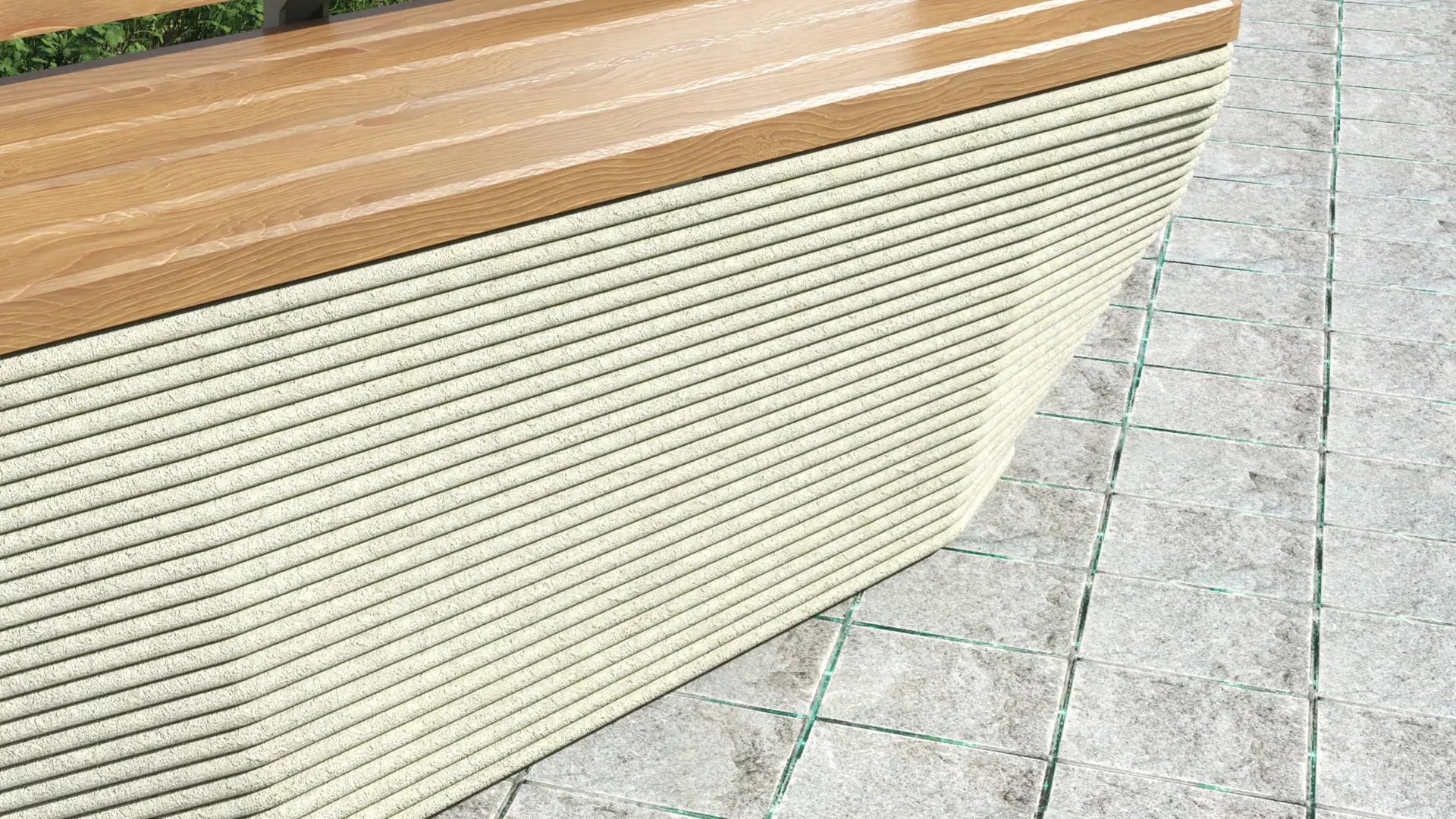

CUS 1053 Concrete Bench, a stylish and durable member of the Onyx Series. Produced with concrete material, this bench can be easily used in outdoor areas. Thanks to its simple and modern design, it offers an aesthetic seating area in various open spaces such as parks, gardens, and squares. Its durable structure provides long-lasting use and is resistant to weather conditions. The wooden seating area offers a comfortable user experience.

Our story started with a dream. As Cemer Playground Equipment, with the awareness of being one of the pioneers in the industry, we have been managing the whole process from idea to production based on safety for 30 years. We provide you confidence.

ASTM • ADAOur Cemer USA products meet ASTM and ADA standards;they provide safe and inclusive playgrounds.

cemer.us →