The 3D Model and 3D Printer Revolution in Playgrounds

- Homepage

- The 3D Model and 3D Printer Revolution in Playgrounds

The 3D Model and 3D Printer Revolution in Playgrounds

Today, playground design is no longer limited to producing safe and durable equipment. Elements such as aesthetics, ergonomics, and user experience are now at the forefront of the design process. This is where industrial design plays a crucial role. Technologies like 3D modeling, 3D printers, and digital sketch tools are revolutionizing how modern children's playgrounds are imagined and built.

A New Era in Playground Design with 3D Models

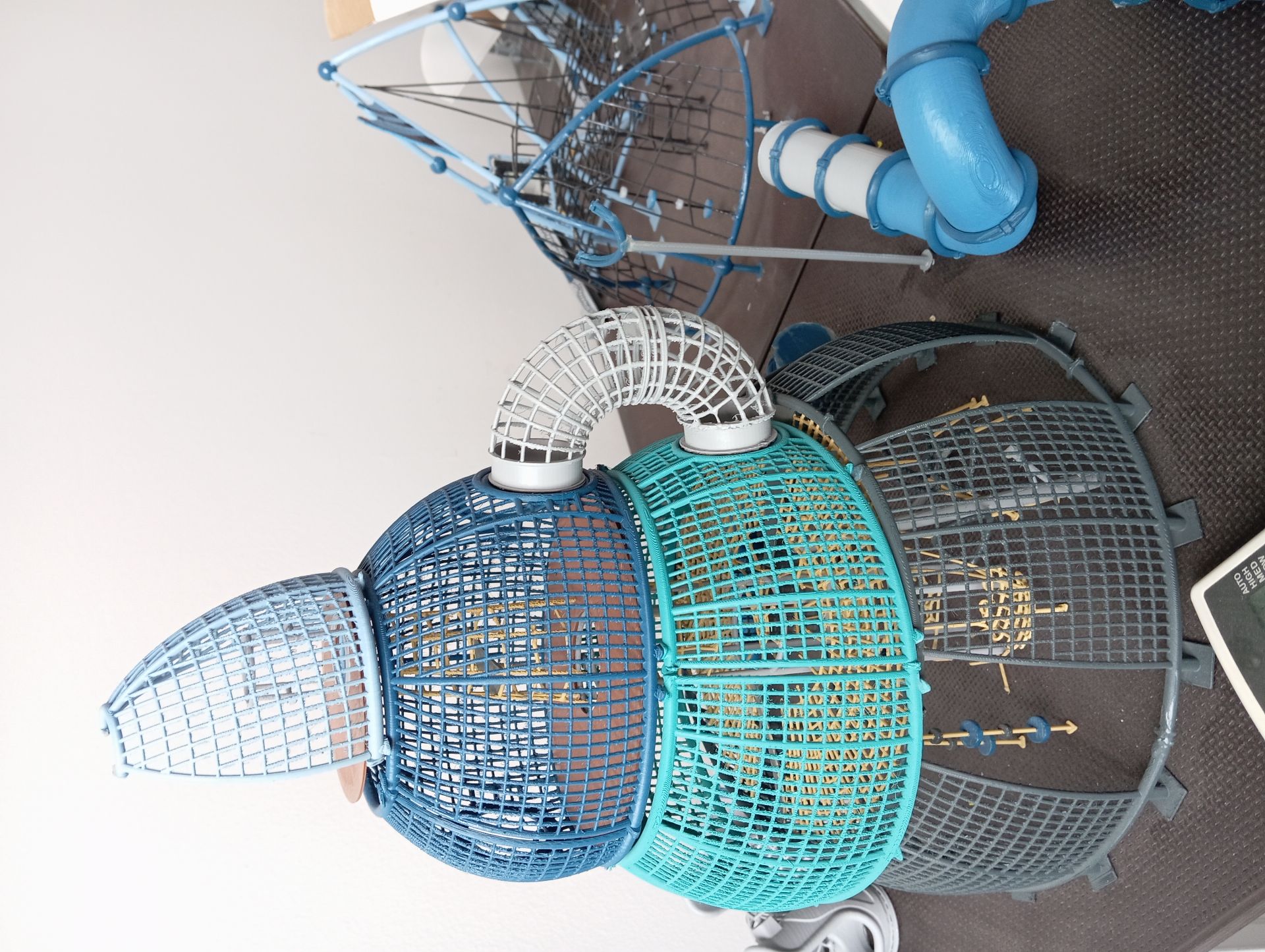

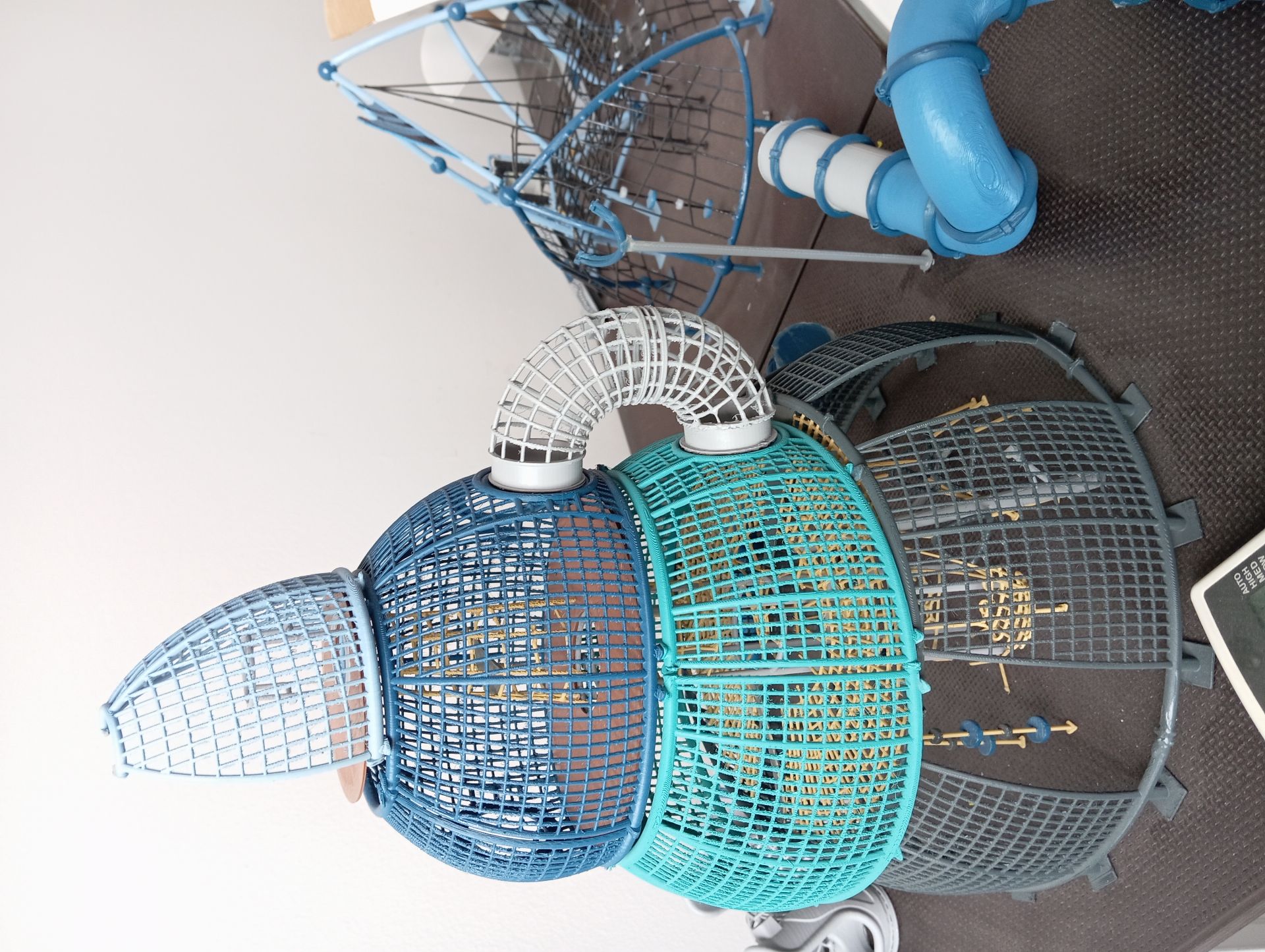

For a playground manufacturer, one of the most essential stages is the creation of a 3D model. These models help visualize all components—whether it's a playground carousel, climbing unit, or balance game—and evaluate their suitability for children's physical interaction and overall safety.

-

Each element of the modern park design is first modeled digitally.

-

The 3D models are tested with animations before physical production begins.

-

Behavior of the playground area is simulated under different scenarios to refine the design.

3D Printers and Rapid Playground Prototyping

In the world of industrial design, the use of a 3D printer accelerates the prototyping phase. Especially in custom-designed playground areas, designers produce scaled prototypes to test ergonomics, safety, and visual style.

-

Time is saved by quickly prototyping even the most complex parts.

-

Clients can visualize the final design with high accuracy.

-

Engineers can begin safety and usability tests at early stages.

These prototypes may include parts of larger units or specific elements like a playground carousel, tested for both rotation safety and interactive appeal.

From Sketch to Real-World Playground

Every great children’s playground begins with a sketch. Designers use traditional and digital sketching tools to present their creative concepts. These sketches are then turned into 3D models, printed using 3D printers, and finally manufactured for installation.

-

Sketching lays the foundation for creative and ergonomic playground design.

-

The design process typically follows: Sketch → 3D Model → 3D Printer → Production.

-

This loop ensures both creativity and efficiency in producing unique, safe, and engaging playgrounds.

Whether you are designing a themed playground carousel, a futuristic climbing zone, or an interactive sandbox, modern tools like 3D modeling, 3D printing, and industrial sketching are shaping the future of children's playground manufacturing.